Glovebox Pass-through valve

15 Luglio 2020

Valve: High Volume Feeder Valve

Handling / Material: Pharmaceutical powders

Client / Industry: OEM, Pharmaceutical processing

Geo Location: Belgium

Application required:

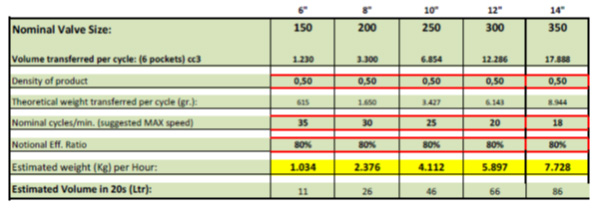

- Feeder valve capable of discharging 88 Ltrs of product in 20s

- TC end connections to fit 12” ferrules

The problem

As drive speed increases, the rate of increase of the discharge volume of a feeder valve reduces, as the pockets fill and empty less efficiently. For high volume discharge there is no alternative to having a large rotor.

In the case in question it was clear that nothing less than a DN350mm rotor would meet the client’s requirements but this had to be shoehorned into a 12” chute.

The solution:

Making use of the fact that the inside surfaces of the Valvengineering Feeder valve are machined spherical to match the shape of the rotor and assure full control of product low at all times, the team designed a custom-built Feeder valve with DN350 rotor and 12” TC end connections.

High precision CNC machining of the valve body and the rotor ensured a close fit between the rotor blades and the valve body. This was possible owing to the careful choice of a highly stable PEEK material for the drive bushings.

All wetted parts were polished to a high mirror finish.

The result

The use of this valve enabled the client to achieve the discharge volumes of a substantially larger valve at acceptable drive speeds while retaining the same nominal passage size.