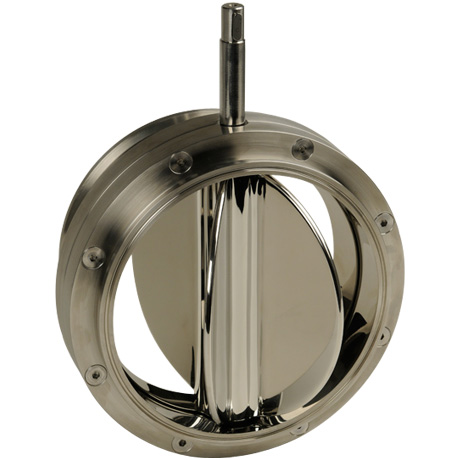

In applications where the required product flow is larger than can be comfortably managed by a rotary valve with pneumatic actuator, we offer a complete range of metal/metal Feeder valves designed for continuous motor drive by electric or pneumatic motor-reducer.

The inside of these valves is machined to a spherical section in order to achieve full control of the product flow at all times.

All Oyster™ branded sanitary valves are designed according to cGMP standards, for trouble free operation and easy maintenance. The valve design ensures optimal hygienic and functional characteristics and eliminates recesses with hard-to-clean corners. Oyster™ branded valves are manufactured to exacting tolerances and finished to the highest pharmaceutical standards.

![]()

FEATURES

| Atex Certification | II 2GD c IIB T4/T135°C Ask for other zones |

| Diameter | DN 100 / 150 / 200 / 250 / 300 – (4”-6”-8”-10”-12”) |

| WIP | suitable for washing in place |

| Operation | electric and/or pneumatic gear motor |

SPECIFICATIONS

| M.O.C. CONTACT PARTS | AISI 316L, C22, (other alloys available upon request) |

| M.O.C. OTHER PARTS | AISI 304 |

| M.O.C. SEALS (all FDA 177.2600 compliant) | SILICONE, EPDM, PTFE, FFKM |

| OPTION | Also available c/w ClamShell clamp (Compact System) |

| AVAILABLE CONNECTIONS | TC BS 4825-3, TC ASME BPE, TC DIN32676, TC ISO2852, TC OSAME A, Weld End, Oyster Docking collar |