Handling / Material: Pharmaceutical powders

Client / Industry: Pharmaceutical manufacture

Geo Location: Spain

Application required:

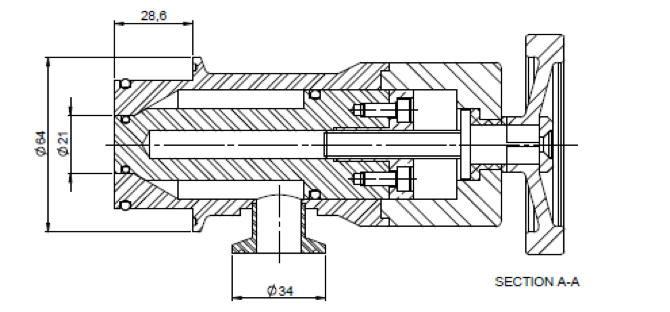

- Hygienic piston valve to port vacuum to pharmaceutical containers during processing

- The existing solution didn’t use a valve and exposed operators to potentially harmful materials

- Tri-clamp fitting into existing location

The problem

In this particular process pharmaceutical product in s/s containers is moved into a processing room where they need to be connected to a vacuum ejector.

The previous solution involved manipulating the containers into place, removing a plug from a 2” TC ferrule and then connecting the hose from the vacuum ejector into the same TC connection.

Routine risk analysis of the process revealed an undesirable risk of operator exposure to the products being handled.

The customer, a well known pharmaceutical manufacturer, asked Valvengineering to come up with a proposal for a valve to handle this procedure based on our successful Samplemaster sampling valve designed for vacuum driers and thereby eliminate the risk of contamination.

The new valve had to be a compact design, easy to operate and maintain and needed to fit into the same 2” tri-clamp mounting ferrules already in place on the host containers.

The project involved fitting 10 valves in total.